First World War: Filling Factories, Explosives and Poison Gas

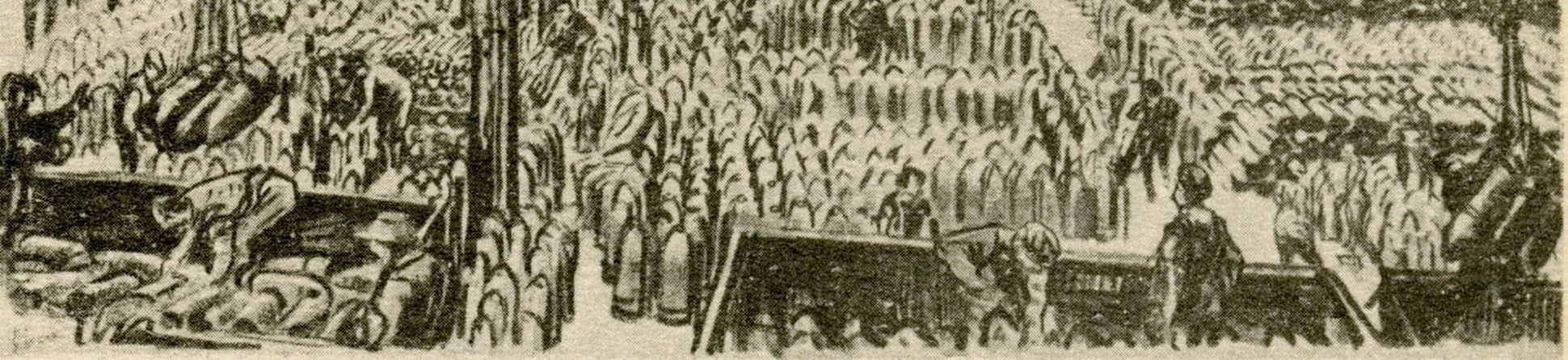

Filling factories assembled the metal and explosive components of various types of munitions - high explosives and cartridges, trench warfare supplies, and poison gas.

From the summer of 1915 the country’s ammunition filling capacity was greatly expanded by the creation of new National Filling Factories. The first was commissioned at Hereford, now listed, as are the earthwork remains of the Banbury factory in Oxfordshire.

The discharge of poison gas by the Germans in April 1915 marked a new and ghastly phase of industrialised warfare. British poison gas production was centred on the dyestuffs industry mainly located in the north-west of England. Initially at the Front, the British released gas from cylinders, but concentrated bombardment from shells was more effective. Experiments into poison gas shell filling were undertaken at Woolwich and a purpose-built factory was created at Greenford, West London. Other obsolete filling facilities were converted to gas filling.

-

First World War: Land

One of the features of industrialised, mechanised, 20th-century warfare was its hunger for land.

-

First World War: Sea

At the outbreak of the First World War Great Britain was the world’s greatest naval power.

-

First World War: Air

Historic England has identified the most significant airfields and airfield buildings of the First World War.