Low and Zero Carbon Technologies

Low and zero carbon (LZC) technologies generate energy from renewable or low carbon sources and emit low or no carbon dioxide emissions.

In 2019, the UK Government announced a target of net zero for UK greenhouse gas (GHG) emissions by 2050. Reaching net zero requires reducing emissions across the country, including historic properties, whether businesses or households. Low or zero carbon technologies that generate electricity or heat or both with low or no carbon dioxide (CO₂) emissions are vital to meeting this target.

In assessing the benefits of these low and zero carbon energy sources for historic buildings, you will need to consider:

- Does it suit the particular building and use?

- What are the carbon reduction benefits?

- Will the potential savings exceed the whole-life energy costs?

- Can the system be fitted safely without significantly impacting the building and its historic fabric?

- What will be the visual impact on the setting of the building or heritage asset?

- Are there any planning controls that affect your choice and positioning of the installation?

These technologies (particularly those used for generating heat) are more effective within buildings with a highly energy-efficient fabric, where heat demand and loss have been reduced to a minimum.

The output of many of these energy supplies can fluctuate. They will often need to be balanced with electricity supplied from the National Grid, importing or exporting as required.

Apart from the initial set-up costs, operation and maintenance costs, and de-commissioning of redundant systems need to be considered. These can be higher than for conventional supplies. Some systems can also have relatively short lifespans, which can have implications for life-cycle value.

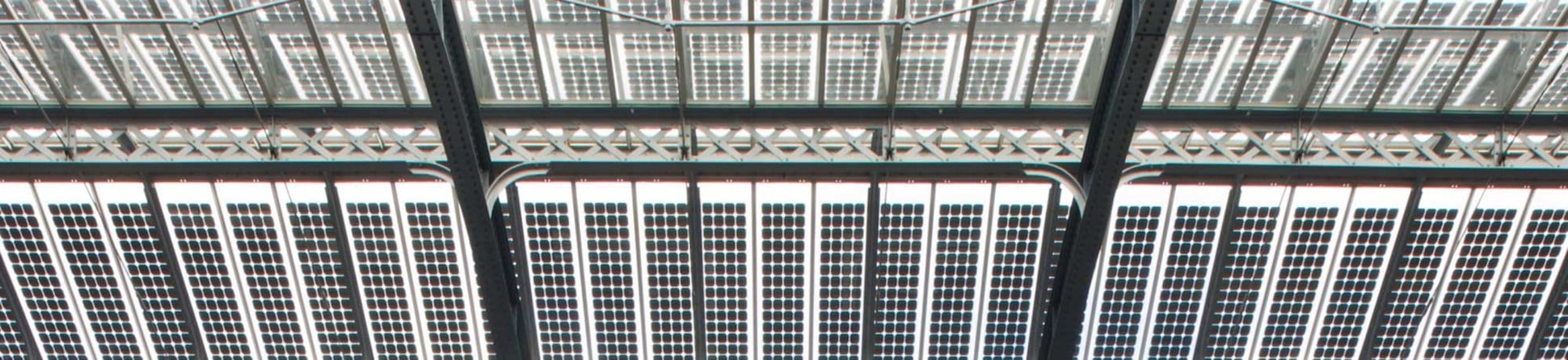

Solar panels (photovoltaics)

Solar panels, also know as photovoltaic (PV) systems, convert sunshine directly into electricity. They can be suitable for mounting on historic buildings where this is possible without compromising their appearance.

PV panels can be mounted atop roofs, but the panel orientation and tilt, visual impact and structural bearing must be carefully considered. Practical installation issues include access for maintenance, availability of internal floor space for ancillary equipment, and how and when electricity is needed within the building.

The design and installation of a PV array needs to be carefully considered, so that their efficiency can be maximised and the impact on a historic building and its setting is minimised.

Installing Solar Panels provides advice when planning an installation on or within the setting of heritage buildings.

Solar water heating

Solar water heating, or ‘solar thermal’ systems, convert the sun’s energy to generate hot water. A heat transfer fluid is pumped through a solar heat collector, which absorbs thermal energy to generate hot water that can be stored for use within a building.

Both direct sunlight and indirect (diffuse) sunlight can be used to generate hot water. Unlike photovoltaic panels, solar thermal systems do not need to be in direct sunshine. Geography and location influence the overall energy yield. However, a range of solar thermal technologies are available that are designed to operate efficiently in different climates. Evacuated tube collectors operate best in cloudy sky conditions and suit installation in the UK. Conversely, the flat plate collector better suits geographies with greater direct sunshine.

Key considerations for these systems are similar to influencing factors outlined for photovoltaic system installations. An important distinction is that greater internal space may be required for the storage of thermal energy via a hot water cylinder. Solar thermal systems may provide useful energy in offsetting heating demand, which would otherwise be served from the main building heating system. However, for most applications, a dispatchable energy source (such as a gas boiler) will be needed to boost heating during times of peak demand.

Further advice on solar water heating is available from the Energy Savings Trust

Heat pumps

Heat pumps offer an efficient, low carbon means of space heating and hot water for many historic buildings.

Heat pumps work by using refrigerant to absorb and release heat energy from the outside air, bodies of water, or the ground. The refrigerant is compressed from a low temperature to a higher temperature and then condensed back into a liquid to release its stored heat.

The design and installation of a heat pump needs to be carefully considered, so that its efficiency can be maximised and the impact on a historic building and its setting is minimised.

Installing Heat Pumps in Historic Buildings provides advice on installing air, ground or water source heat pumps in historic buildings.

Wind turbines

Wind turbines operate by extracting kinetic energy from the wind. The transfer of energy rotates the turbine, which drives an electric generator. Smooth and efficient wind turbine operation is highly sensitive to the direction, consistency and uniformity of the available wind resource. Turbines can be mounted near buildings, but may be visually intrusive or create noise and shadow flicker issues.

Installations are likely to require planning permission as well as heritage consents.

Summary of considerations when planning wind turbines

Available energy:

- Location and siting

- Historical wind data (long-term wind profile)

- Terrain type (short-term wind profile)

Equipment:

- Type of turbine (classification, controls, and so on)

- Duration of time operating at rated output

- Ancillary equipment power and conversion efficiencies

Uses:

- Demand type (decentralised, UK grid supplying, and so on)

- Connection to supply (synchronisation, system balancing, and so on)

- Appropriate ongoing maintenance

Case Study

There have been several examples of community-owned wind turbines in the UK. Mean Moor wind farm is a community-owned wind farm in Cumbria, comprising of three 2.3 MW (megawatt) wind turbines. The electricity generated from Mean Moor is fed to the grid and expected to power approximately 4,500 homes per annum. Local ownership of wind turbines helps to maximise the regional economic benefits from the harnessing of a renewable resource. The initiative has been successful for income generation and for the preservation of the local economies, despite the potential visual detriment to the natural landscape.

Further advice is available on our Wind Energy web page.

Hydroelectric power

Hydroelectric power uses the energy stored in bodies of water to generate electricity through a water turbine. The power output is dependent on the volume flow rate and height through which the water falls (the ‘head’). Hydroelectric power generation can vary in scale of power output, but the fundamental principles for energy generation remain the same, which involve diverting water to drive a turbine. Due to the high level of environmental intervention required, capital costs for hydroelectric projects are often substantial, making them more suitable for large-scale generation and long-term operation.

A high degree of maintenance is required, particularly for parts exposed to the water. This may involve clearing screens of debris, cleaning filters and more generally, ensuring that the body of water is healthy. In addition, the mechanical and electrical equipment must be routinely serviced.

Systems usually require Environment Agency approval and conditions can be onerous. An environmental impact assessment will usually be a condition of any planning consent.

Micro-hydro schemes have a typical arrangement involving flow diversion from a water body and channelling this towards the pump house at a lower elevation, before discharging water back to the water body. The key considerations are rainfall catchment area, flow regimes, visual impacts of the dam or weir, the environmental impact of diverting a water flow, the impact of the pipeline to transport the water to the turbine, and the outflow where the water returns to the water course.

Hydroelectric generation is often well-suited to sites with historic significance, particularly sites with historic watermills. More broadly, these sites may contain:

- buildings such as watermills with existing mill wheels

- buildings that were once mills but have since been converted to other uses, so only remnants of the original use are visible

- sites with existing infrastructure suitable for a hydroelectric scheme, or

- other sites where the potential for hydroelectric generation has been identified.

Such sites can often be in isolated areas, where on-site generation can cost less than installing a connection to the National Grid. Location can bear strong significance on the project scope and overall economics. An example is the National Trust’s Gibson Mill, a 17th-century cotton mill.

Micro-Hydroelectric Power and the Historic Environment provides further advice on micro-hydroelectricity schemes and historic sites.

Summary of considerations when planning hydroelectric power

Available energy:

- Location and scheme layout

- Flow duration curve

- Hydraulic head available

Equipment:

- Type of turbine (classification, controls, and so on)

- Duration of time operating at rated output

- Ancillary equipment power and conversion efficiencies

Uses:

- Demand type (decentralised, UK grid supplying, and so on)

- Connection to supply (synchronisation, system balancing, and so on)

- Appropriate ongoing maintenance

Case study

The National Trust’s video 'Power from the past lights up Cragside' describes the Trust’s green energy project at this Grade I listed Northumberland home. In 1883-87, Lord Armstrong built a hydroelectric turbine system to generate electricity for his house. The powerhouse is listed Grade II* and includes a Thompson double vortex turbine and an R E Crompton double magnet 'Trade'-type Gramme ring compound dynamo, which is the earliest known surviving example. The new Archimedes screw turbine produces enough energy to light all 350 light bulbs in the house.

Combined heat and power (CHP)

Combined Heat and Power (CHP) systems provide both electricity and heating. The principle of operation is based on capturing heat produced during electricity generation from combustion processes that would otherwise be wasted and using this as a heat supply. CHP systems can offer significant efficiency savings in comparison to combustion-based electricity production alone. They are often applied in district heating schemes where there is a predictable electricity demand.

CHP systems perform best operating under constant demand profiles; therefore, they are often installed where there is a predictable and steady large aggregate demand. Where a demand for both heat and electricity exists in the same location, CHP can reduce energy costs whilst reducing carbon emissions and air pollution. They are used widely for university campuses, housing developments and manufacturing facilities.

CHP schemes can encompass a range of different generation technologies and can be fuelled by fossil fuels or renewables. Traditional CHP systems use fossil-fuel-generated electricity, which means that they are not a net zero carbon technology. Natural gas CHP is recognised as a ‘bridging fuel’ that could bring efficiency benefits whilst transitioning to lower carbon fuels. The future for CHP would be to use zero carbon fuels such as hydrogen for the combustion process.

The government provides support to improve the commercial case for investing in CHP because of its relatively long payback period, the environmental benefits of cogeneration, and its technical complexity. The CHP Quality Assurance Scheme (CHPQA) is an annual assessment process that ensures that all CHP plants that benefit from government support meet a required level of energy efficiency.

Advantages of CHP systems are best realised when applied at scale. Efficiency gains can offer a lower cost option to grid electricity. Distribution and transmission losses are reduced through a district energy network and operators can save on energy bills. Additional benefits include the ability to modulate output during peak demand, security of supply during network outages, and heat storage which should be incentivised to encourage flex within the grid.

For further advice, see the government’s Department for Business, Energy and Industrial Strategy guidance on CHP support.

Biomass boilers

Biomass boilers are like conventional boilers but use wood chips or pellets as fuel to generate heat. In doing so, they are carbon neutral as emissions from the combustion process are balanced by the planting and regrowth trees, which sequester carbon dioxide during their lifetime.

Biomass boilers tend to be larger and fully automated systems. They have an auger to feed the boiler, a hopper, and a fuel and ash storage area. Due to combustion of a solid fuel, biomass installations require more frequent and complex servicing than conventional oil or gas boilers. Boilers need to be cleaned regularly in order to keep them free of ash, and the feed systems need to be checked weekly.

Biomass fuel can be bought commercially, or harvested and processed locally, but supplies need to be from Forest Stewardship Council (FSC) certified sustainable sources. Biomass must therefore be dispatchable, and the fuel store needs to be dry and big enough to keep enough stock of chips or pellets to minimise the number of deliveries. Incorporating the indirect carbon emissions from fuel deliveries and logistical operations, a poorly operated biomass installation may not be carbon neutral. Regular delivery of biomass pellets may preclude certain sites with limited access and must be taken into careful consideration in heritage sites, which may be in remote locations. Guaranteeing long-term supply chains is essential, as the operation of a biomass system will be dependent on the regular availability of biofuel.

Biomass boilers are covered by several regulations including the Clean Air Act. Local authorities have the powers under this act to request the measurement of dust emissions from biomass boiler exhaust stacks and require arrestment plant to be installed to control dust emissions. Where the local authority has designated a ‘Smoke Control Area’, biomass boilers must be approved as an 'exempt appliance'. Biomass energy generation is unlikely to be acceptable in urban areas due to the emissions and issues surrounding entrapment of air within built-up regions.

Further advice on biomass fuel is available from the Energy Savings Trust.

Case study

The National Trust has installed a biomass boiler at Dyrham Park as part of a new conservation heating system to help preserve the English tapestries and Dutch paintings. The wood chip is sourced from woodlands just north of Dyrham Park. The chips are a woodland management by-product and the supply chain can be overseen effectively.

The National Trust has also installed biomass boilers at other historic properties: Croft Castle, Barrington, Dunham Massey and Killerton.

Fit for the Future network

Led by the National Trust, Fit for the Future is a cross-sector network supporting hundreds of practitioners to make their organisations more climate-friendly, adaptive and resilient in order to achieve carbon net zero targets. Historic England and other heritage organisations are members.

The network helps people share ideas and practical experiences through events, workshops, showcases, newsletters and online resources.

Learn more

View our webinars

Climate change adaptation: Low carbon heat sources – 2020

Heating and hot water for buildings make up 40% of energy use and 20% of greenhouse gas emissions in UK buildings. In order to reach net zero emissions by 2050, the question is: what will the future of heat in our buildings look like? As we move away from the familiar fossil fuels like natural gas and oil, what does that mean for older buildings? This webinar looks at what the future could look like for heating and discusses the options available.

Use of heat pumps in historic buildings – 2022

This webinar looks at heat pump technology and practical considerations when installing heat pumps in historic buildings.

For the best webinar experience, please use Google Chrome browser or download Adobe Connect.

The Future of Heating conference – June 2022

Organisations and individuals charged with managing historic buildings face a significant challenge. How do we respond to the climate crisis, whilst ensuring the people using our buildings are comfortable and protect the precious fabric and interiors? How do we make changes urgently, whilst minimising the risk of maladaptation? How do we heat buildings in the context of UK net zero targets, UK energy strategy and increasing energy costs?

Historic England partnered with the Fit for the Future network and the Church of England to deliver The Future of Heating conference. The conference provided an opportunity to learn about solutions to the challenges of heating historic buildings now and in the future.

View the recordings of the conference presentations:

- Dee Nunn (Lead Renewable Energy Project Manager, National Trust) – Decarbonising heat at the National Trust

- Dan McNaughton (Senior Building Services Engineer, Historic England) – Carbon reduction options for churches using oil for heating

- Andrew McQuatt (Engineering Standards Project Leader, Max Fordham) – The viability of air source heat pumps in historic buildings

- Matt Fulford (Director, Inspired Efficiency) – The reality of delivering decarbonised heating in heritage buildings

- Faithful K. Chanda (Community Energy Development Engineer, Western Power Distribution) – Managing capacity of the distribution network (community energy)

- Bill Watts (Senior Partner, Max Fordham) – The future of hydrogen for heating

- Samie Kayani (Director at IK Architecture and PhD researcher, Centre for the Study of Architecture and Cultural Heritage of India, Arabia and the Maghreb, University of Liverpool) – Mosques and carbon neutrality; An opportunity for engagement

- Dr David Warwick (Technical Director, Building Performance, TGA Consulting Engineers) and Matthew Cole (Technical Director, TGA Consulting Engineers) – Application of heat pumps in historic buildings (including a case study on Newcastle Cathedral)

- Dan McNaughton (Senior Building Services Engineer, Historic England) – Learn how to survey a historic building and appraise the heating options

- Paul Lankester (Conservation Scientist, English Heritage) – Conservation heating in historic buildings at English Heritage

- Dr Yousaf Khalid (Research Associate, Durham University) – Net Zero options for heritage buildings

- Panel session on technical solutions to heating historic buildings

- Panel session on policy and advocacy overview