Metals in Conservation

Metals are extremely versatile and can perform tasks that are impossible for other building materials. Each metal or alloy has unique characteristics and properties that govern how it can be used for architecture, art and ornament.

All metals traditionally used in buildings react with oxygen in the atmosphere in a process known as oxidation. Sometimes oxidation produces stable and protective patinas, but in other situations it can result in harmful corrosion that disfigures and seriously weakens the metal. Corrosion is usually a very gradual process and can often be slowed or prevented altogether by good maintenance and the use of protective paints and coatings.

Lead

Lead has been used in building since Roman times, and for many centuries it was the material of choice for the most prestigious royal and ecclesiastical buildings. It is generally very durable and can last hundreds of years. It can also suffer from serious underside corrosion leading to failure in as little as 15 years.

Historic England has undertaken extensive research to understand the causes of underside corrosion. You can read more about our research into the deterioration and conservation of lead on our page on Lead Roofs and Statuary: Understanding, Monitoring and Conservation.

Lead theft

Another threat to historic lead is theft. Roofs are often the target but thieves also take gutters, downpipes and lightning conductors. Such crimes leave buildings vulnerable to further damage through water penetration. Historic England works closely with the police and various church authorities to tackle this problem. Read more about our advice and guidance on dealing with metal theft from historic buildings on our page on Theft from Places of Worship.

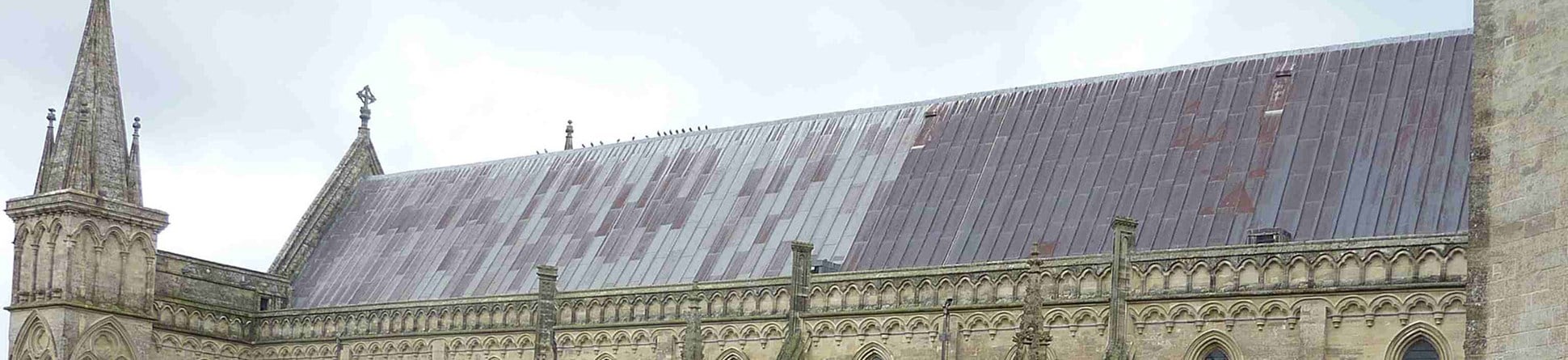

Alternatives to lead

Following the theft of lead from a church roof, there may be occasions when re-covering the roof with terne-coated stainless steel, rather than lead, may be appropriate. This more closely resembles lead compared to other modern alternatives, is extremely durable and has little salvage value so is less likely to be targeted by thieves in the future. Historic England commissioned expert advice on some of the issues regarding the use of terne-coated stainless steel on church roofs. You can download a PDF of the guidance here:

Watch our Technical Tuesday webinar on Terne-Coated Stainless Steel: its use as a replacement material after lead theft from church roofs.

If you’d like to learn more about Historic England’s research to address the problem of rain-drumming noise on terne-coated stainless-steel roofs, you can read our report: Historic England Research Report 55/2021 - Rain Noise: Acoustic Tests on Terne-Coated Stainless-Steel Roofing.

Conserving architectural metalwork

The field of architectural and structural metalwork encompasses a wide range of structures that vary in size, materials, significance and complexity: from engineering structures and bridges, to railings, rainwater goods or window frames, from fountains and statuary to catches, nails or simple hinges.

The webinar below covers what we mean by architectural and structural metalwork, the main metal groups (ferrous and non-ferrous), their properties and some typical problems, as well as a general approach to their conservation.

2021 webinar: Introduction to conservation of architectural metalwork

Conserving iron gates and railings

Traditionally, gates and railings were made from wrought iron, cast iron and, later, steel. Sometimes the entire structure was made from a single type of metal, but in other cases different components could be in different metals (some in wrought iron and others in cast iron, for example). Regular maintenance is essential to keep iron gates and railings in good repair.

The webinar below gives an introduction to wrought and cast-iron gates and railings. It describes fabrication methods, as well as the properties of the different metals used and some typical features to help recognise them. Common condition problems, assessment and options for cleaning, repair, and coatings, as well as general advice on maintenance are also covered.

2021 webinar: Conservation of architectural metalwork: Iron gates and railings

Conserving historic steel-framed windows

Steel-framed windows contribute to the historic significance of those buildings in which they are found. You can read more about the heritage values of historic steel-framed windows, their deterioration, maintenance and repair in this short article.

The article also discusses the case study of Stow Maries Great War Aerodrome and its rare collection of 24 First World War buildings, which are listed Grade II*. These were hastily constructed using single-skin brickwork and early steel windows (pre-dating standardisation); they were not designed to last. The buildings are now well over 100 years old and, because of their condition and uncertain future, they are on the Heritage at Risk register.

There are more than 100 steel windows at Stow Maries Great War Aerodrome, all of which are affected by corrosion and distortion. However, with the right advice and skilled workmanship, they can be conserved and repaired.

This short film shows trial repairs carried out on two of the steel-framed windows. The trial will inform the work of the Trust as – with the support of Historic England – it develops its conservation programme for the remainder of the windows as part of a wider site programme of conservation.

Looking after metal statuary

It is a common misconception that metal is a strong, tough material. In reality, the metal statues on our streets and in public squares are vulnerable to the weather, vandalism and long-term lack of maintenance. This guidance describes various types of historic metal statuary and common problems associated with it. It briefly explains methods of conservation and maintenance, and when to seek the advice of a metals conservator.

Historically, most metal statuary was made of bronze. To a lesser extent, lead, zinc, cast iron, copper and aluminium were also used to make statues and other large features, such as fountains.

Although metals have common properties, each one has unique physical and chemical characteristics that require specific conservation treatments.

-

Issues Common to all Metal Statuary

Construction methods, problems and treatment techniques common to all metal statuary.

-

Bronze Statuary

Construction methods, problems and treatment techniques specific to bronze statuary.

-

Lead Statuary

Construction methods, problems and treatment techniques specific to lead statuary.

-

Zinc Statuary

Construction methods, problems and treatment techniques specific to zinc statuary.

-

Cast Iron Statuary

Construction methods, problems and treatment techniques specific to cast iron statuary.

-

Copper Electrotype Statuary

Construction methods, problems and treatment techniques specific to copper electrotype statuary.

-

Aluminium Statuary

Construction methods, problems and treatment techniques specific to aluminium statuary.